TOUT

CE QUE VOUS VOULIEZ SAVOIR SUR

TOUT

CE QUE VOUS VOULIEZ SAVOIR SUR

LA PILE A COMBUSTIBLE

FUEL CELLS: STATUS AND PERSPECTIVES

Café des Sciences, CERN/Genève, Cl. ROULET (Schlumberger)

Organisé par l'association Euroscience-Léman

16 novembre 2000

HISTORY

-

PRINCIPLE DISCOVERED BY WILLIAM OROVE (1839)

NASA Gemini program: GE (PEM technology: Proton Exchange Membrane), then

abandoned

NASA Apollo program: United Technologies Corporation, subsidiary IFC (AFC

technology: Alkaline Fuel Cell)

Greatly improved version to provide electrical power to the shuttle

NASA Gemini program: GE (PEM technology: Proton Exchange Membrane), then

abandoned

NASA Apollo program: United Technologies Corporation, subsidiary IFC (AFC

technology: Alkaline Fuel Cell)

Greatly improved version to provide electrical power to the shuttle

- Needs extremely pure H2 and O2

- Prohibitive costs for civil commercial applications

-

PEM Technology development resumed 1984 (Ballard Power Systems with Canadian

R&D money)

To-day main type of fuel cell being developed to power automobiles

Can operate with air and lower grade hydrogen, such as reformed methanol

Expensive catalyst (Pt), problem being solved now by thin layer of microscopic

Pt on electrodes

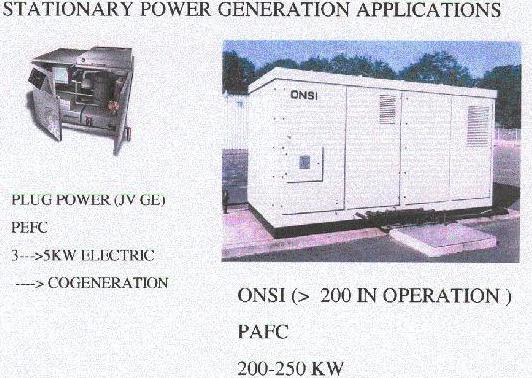

PAFC (Phosphoric Acid Fuel Cell) technology was aggressively developed

(US and Japanese companies)

First type to be commercialized

185 units have been commercialized to date for stationary power generation

(UTC- ONSI) 200-250kW

May operate on impure hydrogen and air

Power output lower than PEM technology

Does not respond well to changing power demand

US government still put tens of M$ into PAFC

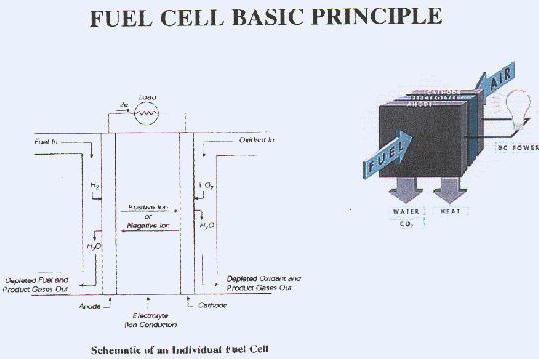

TYPES OF FUEL CELLS

Electrolyte: KOH, operation 120 10 250o C

CO, CO2: poisons, wide range of electrocatalysts

Efficiency Up 1070%

Long used by NASA

Prohibitive cost for commercial applications

-

PAFC: PHOSPHORIC ACID FUEL CELL

Electrolyte: concentrated phosphoric acid, 150 to 220o C

CO poison of Pt electrocatalyst in anode

Easy water management

Efficiency 40%, 85% with cogeneration

The most commercially developed type of fuel cell:

- Diverse applicatons: hospitals,

hotels, office buildings, schools, utility power plants, airport terminals

- Can also be used in large

vehicles (buses & locomotives)

-

PEFC: POLYMER ELECROLYTE FUEL CELL

Electrolyte: ion exchange polymer membrane, excellent proton conductor,

about 80oC

CO poison at low temperature

High catalyst load (Pt) at both electrodes

Only liquid is water, minimum corrosion problems

Critical water management in membrane for maximum efficiency

Efficiency: about 40%

High power density, flexibility to power demand, quick start

- Primary candidates for

light-duty vehicles, buildings, and much smaller applications such as video

cameras

-

DMFC: DIRECT METHANOL FUEL CELL

Similar to PEFC but anode catalyst draws H from liquid methanol, eliminating

need for reformer

Efficiency Up to 40% expected

Early stage of development

-

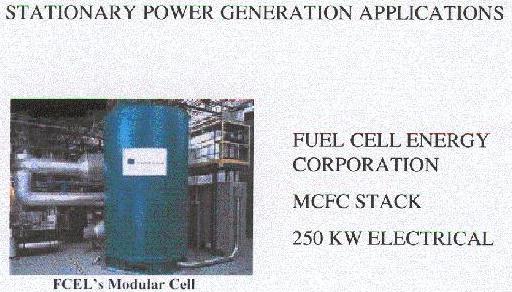

MCFC: MOLTEN CARBONATE FUEL CELL

Electrolyte: combination of Na & K carbonates retained in ceramic matrices

(LiAlO2)

Operation 600 to 700o C

Ni anode, Ni oxide cathode, inexpensive catalysts

High efficiency

Excess heat can be captured and utilzed in cogeneration

Large variety of fuels: natural gas, propane, diesel

- Suitable for ships, remote

places, stationary decentralized power plants

-

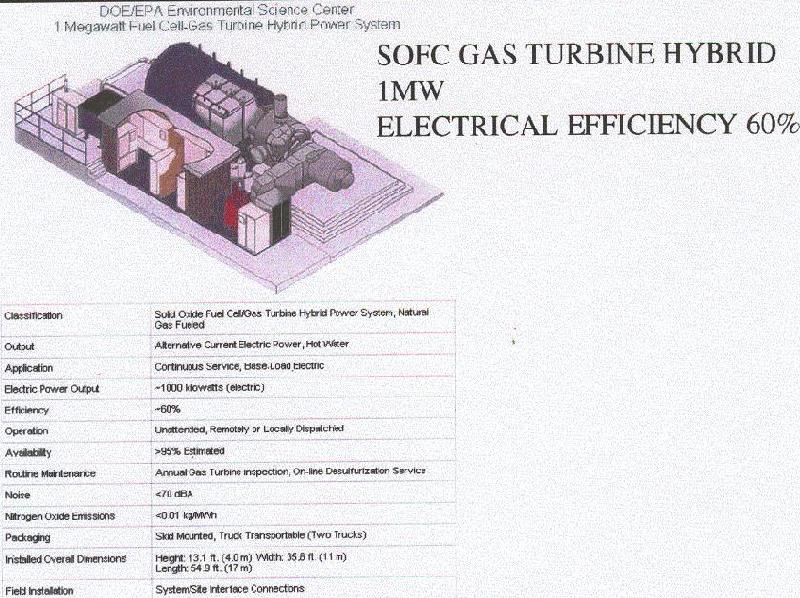

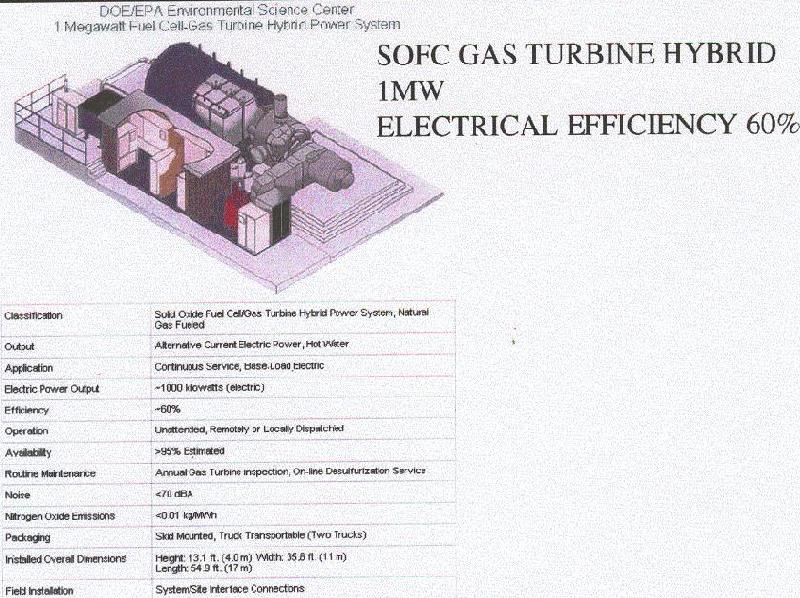

SOFC: SOLID OXIDE FUEL CELL

Electrolyte: solid, non-porous metal oxide, usually Y2O3

-

stabilized ZrO2

Operation 650 to 1000o C

Anode: Co-ZrO2 or Ni-ZrO2, cathode Sr-doped LaMnO3

Cheap catalyst

- Efficiency Up to 60%,

higher with cogeneration

-

RFC: REGENERATIVE FUEL CELL

Very young member of the fuel cell family

Closed loop form of power management:

- Hydrogen and oxygen are

separated from water using a solar-powered electrolyser

- H2 and O2

are fed in fuel cell to produce electricity , water and heat

- Water is recirculated

back to the solar-powered electrolyser

Research conducted by NASA and other front end research centers

MOBILITY APPLICATIONS

TRANSIT BUSES:

AUTOMOBILES:

LOCOMOTIVES

BICYCLES

MAIN COMPANIES

CLEAR LEADER:

- BALLARD & its allies:

DAIMLER-CHRYSLER-FORD

JVs: DBB Fuel cell engines, ECOSTAR Electric Drive Systems

CALIFORNIA CONNECTION:

- Regulation of the California

Air resource Board (CARB):

2003: 4 % of new cars to be ZEV (ZERO EMISSION VEHICLE): 22000 ZEV/YR

- California Fuel cell project:

launched April 1999:

State of California, Daimler-Chrysler, Ford, Ballard, Arco, Texaco, Shell

- New Comers: GM, Toyota,

IFC-Methanex

- 20 FC cars and buses to

be fielded 2000 >> 2003

-

STATIONARY POWER GENERATION

- COMMUNITIES:

- LEADER: IFC

PAFC 200-250 kW

200 UNITS OPERATING

4K$/kW to day to be compared to Gas turbines: 500$ to 1000$/kW

- FECL:

MCFC 250kW

Collaboration with Daimler-Chrysler: MTU

- BALLARD:

PEFC 250 kW to be fielded

- SIEMENS:

SOFC 200kW

- DOMESTIC:

- LEADER: PLUG POWER 5kW PEFC with COGENERATION

- BALLARD

- H-POWER

FUEL ISSUES

-

IDEAL FUEL: PURE H2, BUT…:

- NEW

AND HEAVY INFRASTRUCTURE FOR TRANSPORT

- COMPRESSED H2 TOO BULKY FOR CARS, MAY BE ACCEPTABLE FOR LARGE

TRANSIT BUSES

- LIQUID H2: COMPACT STORAGE BUT COST 30% OF ENERGY

- HYDRIDE STORAGE: VERY PROMISING: from 7 % in weight (ECD) to 11% (LANL)

- PRIME

CANDIDATE:METHANOL

ABUNDANT

CAN BE OBTAINED FROM NATURAL GAS, BIOGAS

- GASOLINE:

PRESENT DEVELOPMENT BY NUVERA, PLUG POWER, IFC-TOYOTA, DAIMLER-CHRYSLER-SHELL…)

- SOURCES:

- VIA REFORMING:

FOSSIL FUELS OIL & GAS

METHANE (CMM,CBM)

STRANDED GAS

HYDRATES

BIOMASS, ORGANIC WASTE

- CO2 SEQUESTRATION POSSIBLE IF CENTRAL REFORMING

-

VIA HIGH PRESSURE ELECTROLYSIS OF WATER

- ELECTRICITY FROM CENTRAL POWER PLANTS

- ELECTRICITY FROM DISTRIBUTED RENEWABLE ENERGY STATIONS:

SOLAR

WINDTURBINES

GEOTHERMAL (EX: ICELANI) TOTAL H2 PROJECT)