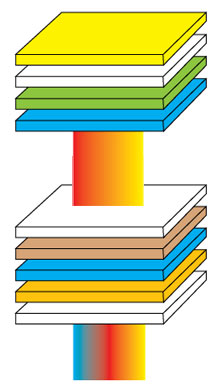

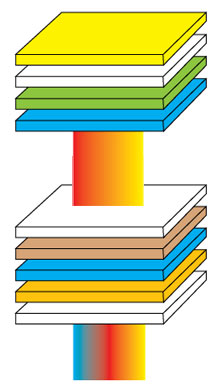

Solar solution: A new type of solar cell uses layers of two

different types of conducting polymers to increase the device’s efficiency.

The design has achieved a record high efficiency for photovoltaics that

use conductive polymers to generate electricity.

A new process for printing plastic solar cells

boosts the power generated by the flexible and cheap form of photovoltaics.

Initial solar cells made with the technique can, according to a report

in today's issue of Science, capture solar energy with an efficiency of

6.5%--a new power record for photovoltaics that employ conductive plastics

to generate electricity from sunlight. Most photovoltaics are made from

conventional inorganic semiconductors.

The new process stacks multiple polymer layers

within a single photovoltaic device to produce a "tandem" cell. Alan Heeger,

who won the 2000 Nobel Prize for his codiscovery of electrically conducting

polymers, and his colleagues at the University of California, Santa Barbara

(UCSB), created the process with a group from South Korea's Gwangju Institute

of Science and Technology. Heeger says that the tandem architecture offers

plenty of room for further improvement--enough to eventually make plastic

solar cells practical in rooftop solar panels. "We see a pathway here

toward even higher efficiencies," he says. "We can do significantly

better than 6.5% in the near future."

Tandem cells, commonly employed in conventional

solar panels, increase power output in two ways. The semiconductors in

the different layers can be optimized to capture different bands of light,

thus enabling the tandem device to absorb a broader spectrum of sunlight.

And the multiple layers boost the voltage of the tandem device, yielding

more power from every photon absorbed. "You do a better job of light harvesting

and a better job of utilizing the photon energy," explains Heeger.

Until now, however, the tandem architecture

spoiled plastic photovoltaics such as Heeger's, which are "printed" by

spraying solutions of conductive plastics and other materials onto a plastic

film. Layers of different plastics sprayed on top tended to mix, degrading

rather than enhancing power output. Heeger and his colleagues beat the

mixing problem by finding an effective spray-on separator to keep the layers

in place.

The bottom cell is filled with a proprietary polymer first disclosed

last year by plastic PV developer Konarka Technologies, based in Lowell,

MA, which Heeger cofounded and for which he serves as chief scientist.

The polymer (a derivative of polythiophene) absorbs both infrared and ultraviolet

light. Next comes a titanium-suboxide layer, which seals in the bottom

cell, provides a foundation for building the top layer, and, as it's a

metal, efficiently carries away the charged electrons generated in both

layers. Finally, the top layer sports a different type of conducting polymer

that absorbs mostly blue and green light.

Heeger expects further efficiency strides

as device developers gain experience with the cell's new materials. For

example, in May, the UCSB researchers reported a processing tweak that

doubles the power output of single cells made with Konarka's new polythiophene

polymer. Heeger says that the processing trick was not used in the tandem

cell.

Yang Yang, a physicist at the University of

California, Los Angeles, agrees that rapid improvement is likely. He says

that such optimization could yield a tandem cell that's more than 10% efficient.

"I would call this important progress," he says. |

Not all experts are as optimistic. Sean Shaheen,

who recently left a research post at the Department of Energy's National

Renewable Energy Laboratory for the University of Denver, cautions not

to overreact to the report. For one thing, says Shaheen, efficiency estimates

are notoriously unreliable because each research group tests efficiency

under its own approximation of the solar spectrum.

Another hurdle for the tandem cell is manufacturing.

Konarka vice president of research Russell Gaudiana expects that the company

would be able to produce Heeger's tandem cells on the same printing lines

it now uses to make prototype modules containing single cells of plastic

photovoltaics, but he says it will be "trickier" to keep the tandem cell's

layers from intermixing in commercial-scale production. "We anticipate

seeing the typical problems that one always sees when putting down multiple

layers," says Gaudiana. "Alan does it in the laboratory and does

a very good job at it, but doing it on a coating machine at high speed

is a little different."

For the time being, says Gaudiana, Konarka

will stay focused on producing single-cell plastic photovoltaics with 5

percent efficiency. That power output is sufficient for Konarka's first

application, portable battery chargers, which the company hopes to begin

selling next year. But tandem cells could help Konarka reach the more demanding

rooftop market, which Gaudiana says will require at least 7% efficiency.

Un tandem de cellules solaires ameliore le rendement photovoltaïque

(pour un rapport détaillé, voir ADIT: "Recherche

et Industrie Photovoltaïque aux Etats-Unis")

Bien que les cellules solaires réalisées

à base de silicium atteignent des rendements de l'ordre de 15%,

leur coût de fabrication important et leur poids élevé

sont des obstacles à leur utilisation massive par les particuliers

ou les industriels. Le photovoltaïque organique peut constituer une

alternative intéressante pour réduire considérablement

le coût et le poids des cellules, mais les rendements actuels des

cellules tout organique sont encore trop faibles (moins de 5%) pour que

cette filière puisse être considérée comme viable.

Une voie intéressante qui permet d'augmenter

le rendement consiste à créer une structure multicouche planaire

comprenant l'équivalent de deux cellules photovoltaïques de

gap différents qui permettent d'obtenir un spectre d'absorption

des photons plus large. Généralement la cellule constituée

d'un matériau semi-conducteur de gap plus élevé est

placée en première position afin de limiter l'énergie

perdue par les paires électrons - trous lors de leur relaxation

dans les niveaux d'énergie inférieurs.

Récemment, une équipe de scientifiques

de l'Université de Californie à Santa Barbara menée

par Alan J. Heeger, prix Nobel de Chimie en 2000, a montré après

avoir observé de façon indépendante les caractéristiques

des deux cellules en fonction de l'épaisseur de la couche active

(constituée d'un mélange de polymère et de fullerène)

que les caractéristiques de conversion photovoltaïque globales

sont améliorées lorsque la cellule constituée du matériau

semi-conducteur de gap inférieur est placée en première

position.

Grâce à cette géométrie,

les chercheurs ont obtenu des rendements de 3.5% 6.7% pour des puissances

lumineuses incidentes respectives 20 mW/cm2 et 200 mW/cm2.

Pour en savoir plus, contact:

Publication parue dans Science

- All-Solution Processing Efficient Tandem Polymer Solar Cells Fabricated

by All-Solution Processing - Jin Young Kim, Kwanghee Lee, Nelson E. Coates,

Daniel Moses, Thuc-Quyen Nguyen, Mark Dante, Alan J. Heeger - Vol. 317.

no. 5835, pp. 222 - 225 (Juillet 2007)

Source: http://www.ia.ucsb.edu/pa/display.aspx?pkey=1634 |